- +86-0316-7210054

- Online consultation

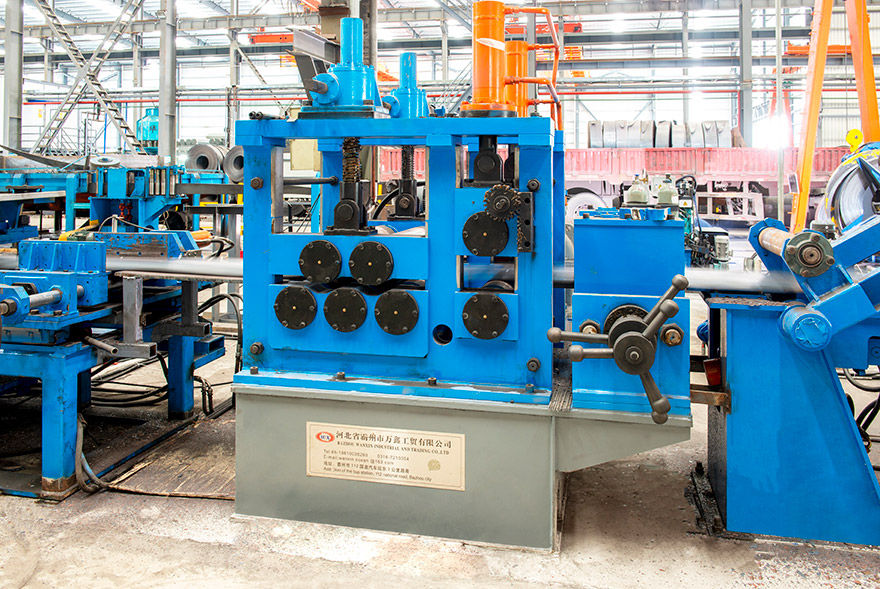

The unit adopts excellent EFX forming system, which has a series of advantages such as stable forming, good surface quality of steel pipe and easy to change specifications. The forming machine is divided into rough forming and fine forming two parts, in which the roll of the rough forming section can adapt to various specifications of steel pipes between 60 square and 100 square, which saves 70% to 80% of the roll than the usual unit. Save roll change and adjustment time, improve unit operation rate. And without the integral roller, equipment investment and spare parts reserve will be greatly reduced.

The fine forming part of the forming machine adopts three fine forming frames and adopts special design for the forming machine. So that the unit can produce thick wall steel pipe, can also produce thin wall steel pipe. The usability of the unit is very strong.

The sizing part of the unit adopts five four-roll frames. So that the unit can produce round pipe, can also produce round square, rectangular pipe, shaped structure pipe.

1. Raw material specifications

Steel strip width: 235-390mm

Steel pipe thickness: 3-6mm

Steel pipe material: Q235, Q355B, etc

Outer diameter range of steel pipe: 1300-1800mm

Inner diameter of steel tube: 620mm

Steel coil weight: ≤8 tons

2. Welded pipe product specifications

Square tube: 50x50-100x100, wall thickness 3-6mm, speed 50-70m/min, length 6000mm

Rectangular tube: 50x70-150x50, wall thickness 3-6mm, speed 50-70m/min, length 6000mm

3. Equipment composition

Simplex uncoiling machine (with straight head machine), shear butt welding machine, pinch levelling machine, spiral looping machine, forming machine (rough forming, fine forming), extrusion frame, deburring device, water cooling device, sizing machine (sizing device, Turkish head), hydraulic electric control

4. Customer on-site shooting