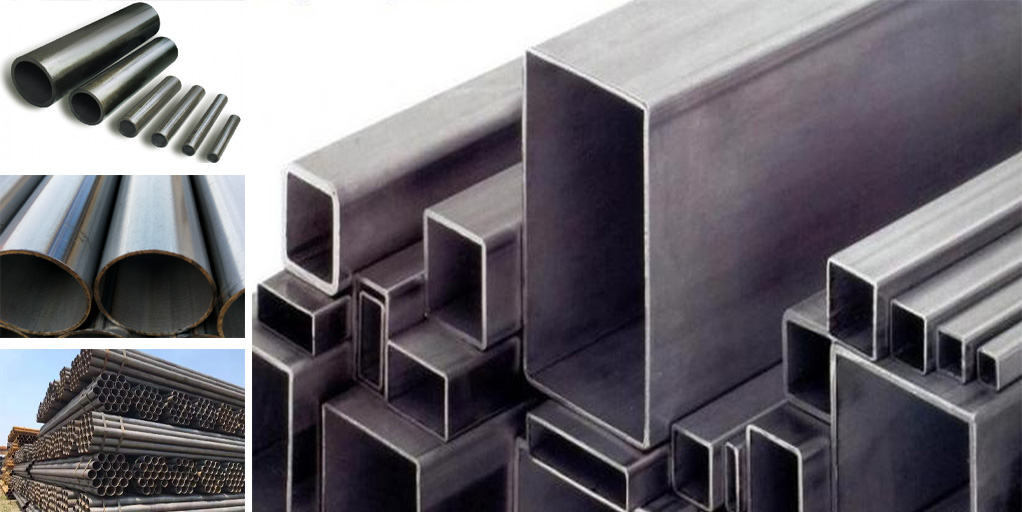

Uncoil the coil in the strip preparation section, and butt weld the end of the coil. The looper is then fed and the strip is pulled out of the looper at a constant speed through the unit. The strip is formed into an open tube in the forming unit. Then it is welded into a straight seam welded pipe with solid high frequency to eliminate the outer burrs and water cooling, and the round pipe and square rectangular pipe are calibrated and shaped in the sizing machine.

Slitting line is used to uncoil and level the the coil plate, slit the steel plate by rotaryshearing unit, then recoil the plate by recoiler, at last pack the coil.

The transverse shear unit is mainly used for leveling, crosscutting and palletizing steel plates of various materials. The large drum plate is unrolled, levelled, and then crosscut into plates according to the required sheet length, and the blocks are stacked neatly by palletizing, and packed into a whole bundle of plates as required.

☑ 20F-400F direct forming line for square and rectangular tube, can carry out the forming changeoperation in a very short time

☑ Great flexibility, without any replacement of rolls, reduce the roll input about 60%

☑ Only need 10-15 minutes to replace one specification, reduce the installation time and lower thelabor intensity

Spiral welding pipe unit is to open the steel coil through the unit equipment, levelling, and then at a certain Angle into the forming machine, the use of three-roll forming principle, supplemented by a certain Angle, to form a continuous round tube, and then the continuous spiral gap with submerged arc welding machine.

Steel pipe hot dip galvanizing production line is a production equipment that automatically dipped the finished black pipe after surface treatment and plated a layer of corrosion-resistant and smooth zinc layer on the inner and outer surface of the steel pipe. The main equipment of the production line includes drying furnace, heating furnace, galvanizing machine, steel pipe extraction machine, drawing mechanism.

Highway guardrail plate forming unit is rolling two wave three wave guardrail plate equipment, the unit can produce three wave steel guardrail plate, by replacing the roll and mold, and can produce two wave guardrail plate. The unit has the following characteristics...

1. Fast speed and high efficiency

2. Small heat affected zone, small deformation

3. Different materials can be welded together

4. Can achieve micro tension control state

The company has a product research and development department, and has various kinds of processing and manufacturing equipment, more than 100 sets of CNC machine tools, can design and manufacture 10mm-660mm high frequency straight welded pipe rolls, various cold formed steel production line rolls, as well as the corresponding specifications of square and rectangular pipe rolls.

The yield strength of the high-strength steel pipe produced by our company is 700-1800mpa, and the tensile strength is 900-2000Mpa. Compared with ordinary steel pipes, high-strength steel pipes, in addition to the advantages of high strength, also has the following advantages: 1, the same specifications and the same strength, the weight is reduced by about 30% compared with ordinary steel pipes