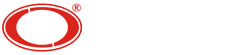

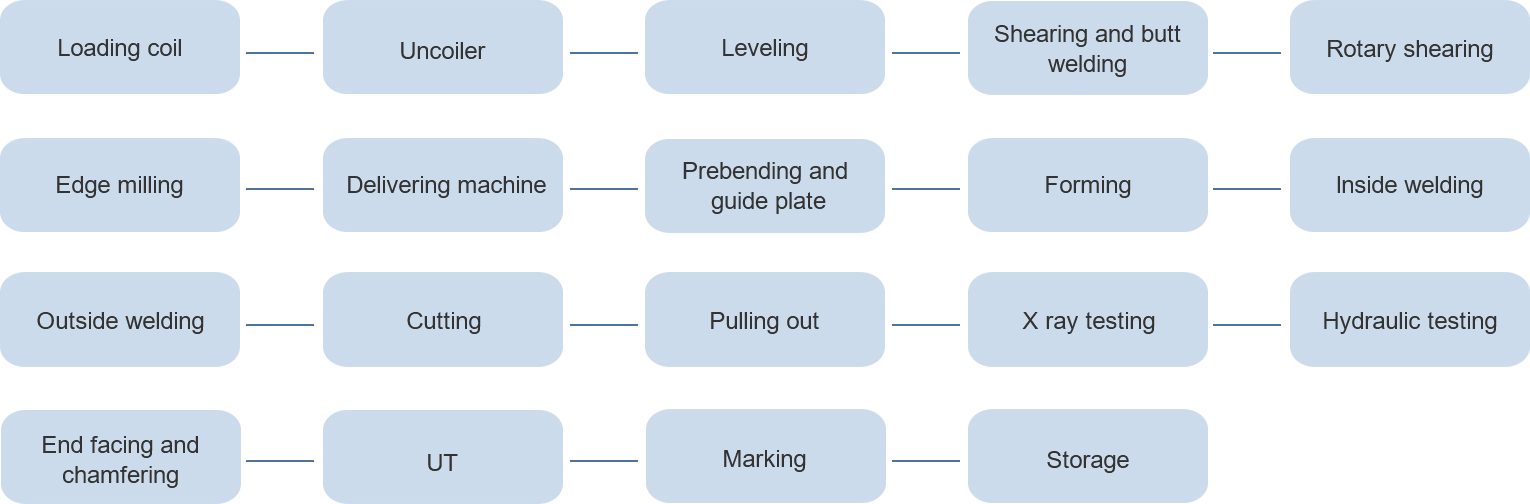

Spiral welding pipe unit is to open the steel coil through the unit equipment, levelling, and then at a certain Angle into the forming machine, the use of three-roll forming principle, supplemented by a certain Angle, to form a continuous round tube, and then the continuous spiral gap with submerged arc welding machine.

The unit is used to produce spiral welded pipe with diameter φ219 ~ φ630㎜ from strip coil with thickness δ=3.5-10mm, width B=400-850mm and steel grade Q345B by opening, leveling, trimming, forming, welding and other processes. The electronic control system adopts Omron PLC automatic control system, digital display system, continental DC speed control system and so on.

Free design drawings, can undertake turnkey projects

24-hour hotline

24-hour hotline

Home

Home Tel

Tel Product

Product