- +86-0316-7210054

- Online consultation

◎ Number of cuts: 3-7

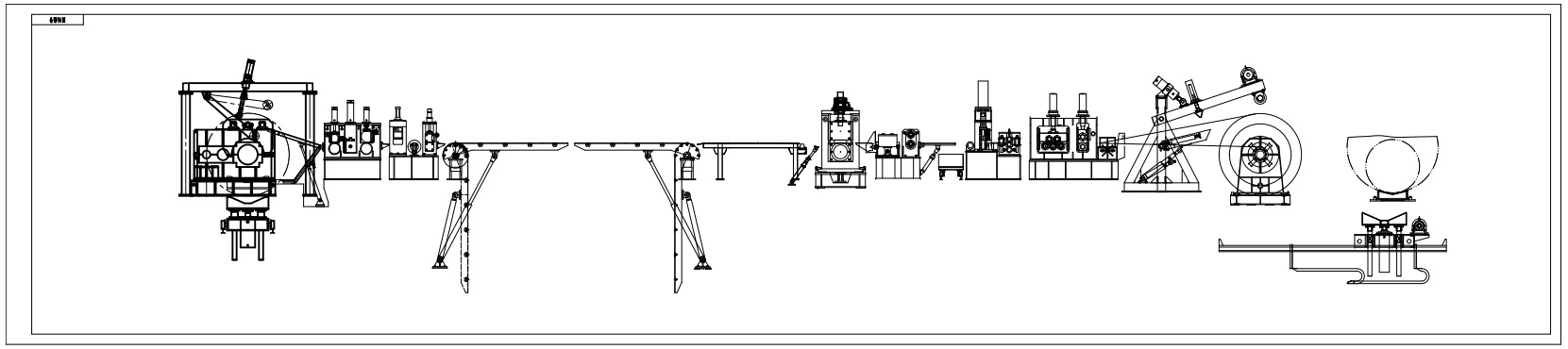

Slitting line is used to uncoil and level the the coil plate, slit the steel plate by rotaryshearing unit, then recoil the plate by recoiler, at last pack the coil.

Slitting line is used to uncoil and level the the coil plate, slit the steel plate by rotaryshearing unit, then recoil the plate by recoiler, at last pack the coil.

Slitting line is used to uncoil and level the the coil plate, slit the steel plate by rotaryshearing unit, then recoil the plate by recoiler, at last pack the coil.

Shear speed: 0-60m/min

Number of cuts: 3-7

Equipment use

It is mainly used to cut the steel strip coil and provide raw materials for pipe steel strip production line. The slitting unit mainly has the following four characteristics:

1) PLC control, hydraulic shear, hydraulic system to achieve partial automatic control. The whole unit is simple to operate, easy to maintain, accurate tension adjustment, and quick replacement of disc scissors.

2) The unit can be active constant tension shear, the size of the tension can be adjusted from the operating table according to the plate thickness and material. The unit is required to adapt to a wide range of slitting thickness. Active cutting and passive tension cutting can also be performed on some thin-walled tape rolls, all of which are cut at constant speed. The quality precision of cutting is high, the quality of slitting is good, and the range of adaptation is wide.

3) Do not bruise and scratch the surface of the strip.

4) Optimization of mechanical production process, short auxiliary production time and high productivity.

Free design drawings, can undertake turnkey projects

Uncoiler

Pinch leveling

Hydraulic shear

Disk shear

Transition platform

Recoiling machine

| Item# | Model | Plate Thickness mm(in) | Coil weight t(ton) | Plate width mm(in) | Cutting speed m/min(ft/min) | Floor area m2(ft2) |

| 1 | ZJ400 | 0.3-4 | 5 | 400 | 30-100 | 10X3 |

| 0.012”-0.157” | 5 | 15.87” | 98.4-328 | 32.8X9.8 | ||

| 2 | ZJ600 | 0.5-4 | 7 | 400-600 | 20-100 | 17X4 |

| 0.02”-0.157” | 7 | 15.7”-23.6” | 65.6-328 | 55.8X13.1 | ||

| 3 | ZJ800 | 0.5-4.0 | 10 | 500-800 | 20-100 | 30X6 |

| 0.02”-0.157” | 10 | 19.7”-31.5” | 65.6-328 | 98.4X19.7 | ||

| 2.0-8.0 | 10 | 500-800 | 30-80 | 30X6 | ||

| 0.079”-0.315” | 10 | 19.7”-31.5” | 98.4-262 | 98.4X19.7 | ||

| 4 | ZJ1000 | 1.0-4.0 | 10 | 600-900 | 30-100 | 30X7 |

| 0.039”-0.157” | 10 | 23.6”-35.4” | 98.4-328 | 98.4X23 | ||

| 2.0-8.0 | 10 | 600-900 | 25-80 | 30X7 | ||

| 0.079”-0.315” | 10 | 23.6”-35.4” | 82-262 | 98.4X23 | ||

| 5 | ZJ1250 | 1.5-6 | 15 | 800-1200 | 50-90 | 32X9 |

| 0.059”-0.236” | 15 | 31.5”-47.2” | 164-295 | 105X29.5 | ||

| 3-10 | 20 | 800-1200 | 20-70 | 32X9 | ||

| 0.118”-0.394” | 20 | 31.5”-47.2” | 65.6-230 | 105X29.5 | ||

| 6 | ZJ1600 | 4-12.7 | 25 | 900-1600 | 20-60 | 32X10 |

| 0.157”-0.5” | 25 | 35.4”-63” | 65.6-197 | 105X32.8 | ||

| 7 | ZJ1800 | 5-14 | 30 | 1000-1800 | 15-60 | 32X12 |

| 0.197”-0.551” | 30 | 39.4”-70.9” | 49-197 | 105X39.4 | ||

| 8 | ZJ2000 | 6-16 | 30 | 1200-2000 | 15-50 | 35X13 |

| 0.236”-0.63” | 30 | 47.2”-78.7” | 49-164 | 114.8X42.7 | ||

| 9 | ZJ2200 | 6-20 | 40 | 1200-2200 | 12.5-25 | 39X15 |

| 0.236”-0.787” | 40 | 47.2”-86.6” | 41-82 | 128X49.2 |

ZJ1600 Slitting line machine diagram

We are engaged in the design, development and manufacture of straight seam welded pipe equipment, high-precision crossbar shear production line, spiral welded pipe equipment, high-frequency welding H-shaped steel equipment, cold-formed steel equipment, hot-dip galvanizing production line and roll.