- +86-0316-7210054

- Online consultation

The hanging plating equipment produced by our company can handle products such as light pole, cable trough, highway guardrail plate, Angle steel, H-shaped steel, channel steel and other products, processing specifications can be designed according to customer requirements.

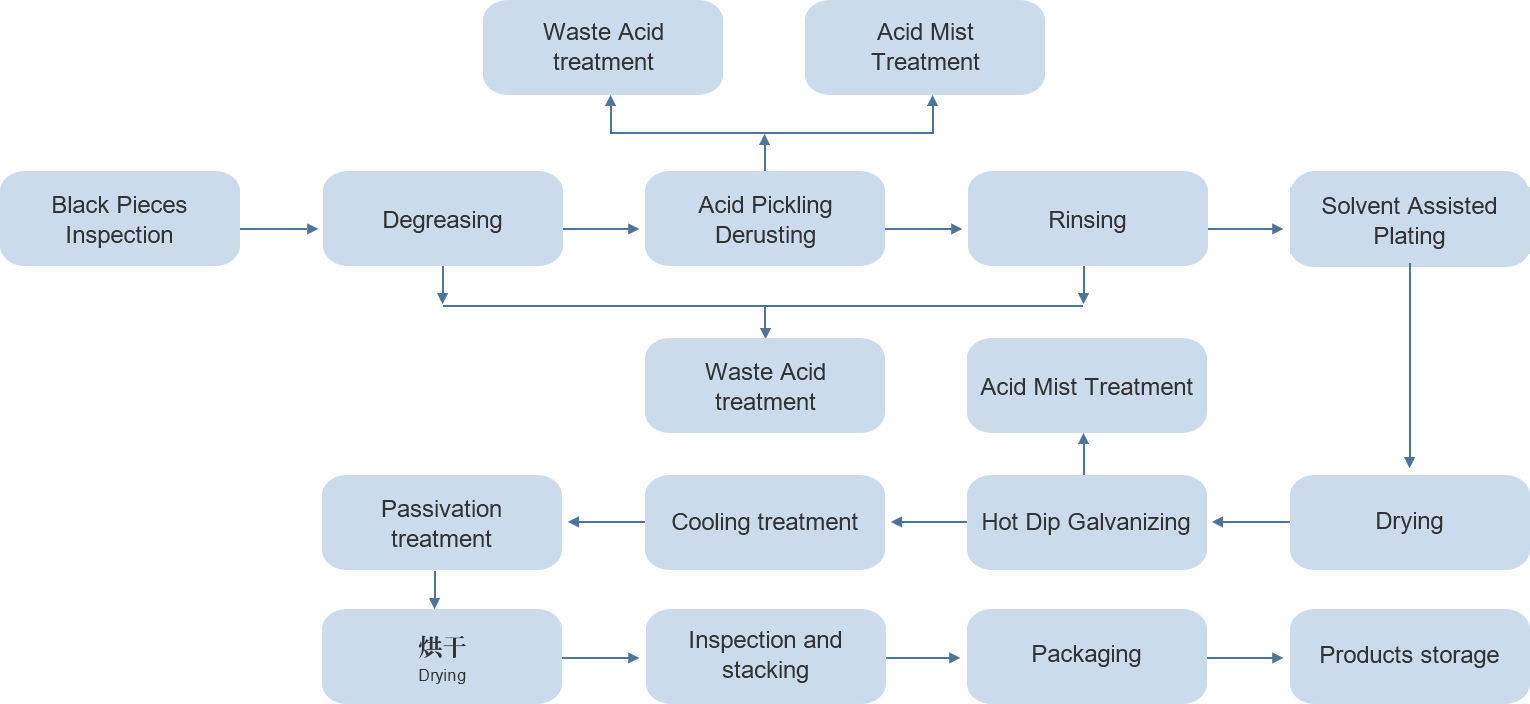

The plating production line process: After the raw materials enter the workshop, the workers will manually hang the plating parts on the spinner with iron wire, lift the suspended plating parts with the crane, go to the next process of pickling, washing, solvent dipping, drying, zinc pot dipping, cooling and passivation, and the plating parts will be taken off by the workers, packaged and stored.

We are engaged in the design, development and manufacture of straight seam welded pipe equipment, high-precision crossbar shear production line, spiral welded pipe equipment, high-frequency welding H-shaped steel equipment, cold-formed steel equipment, hot-dip galvanizing production line and roll.